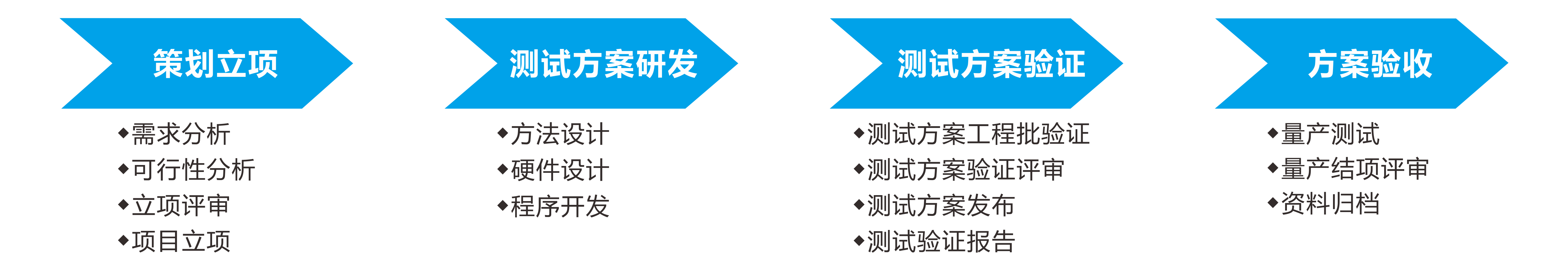

Testing R&D

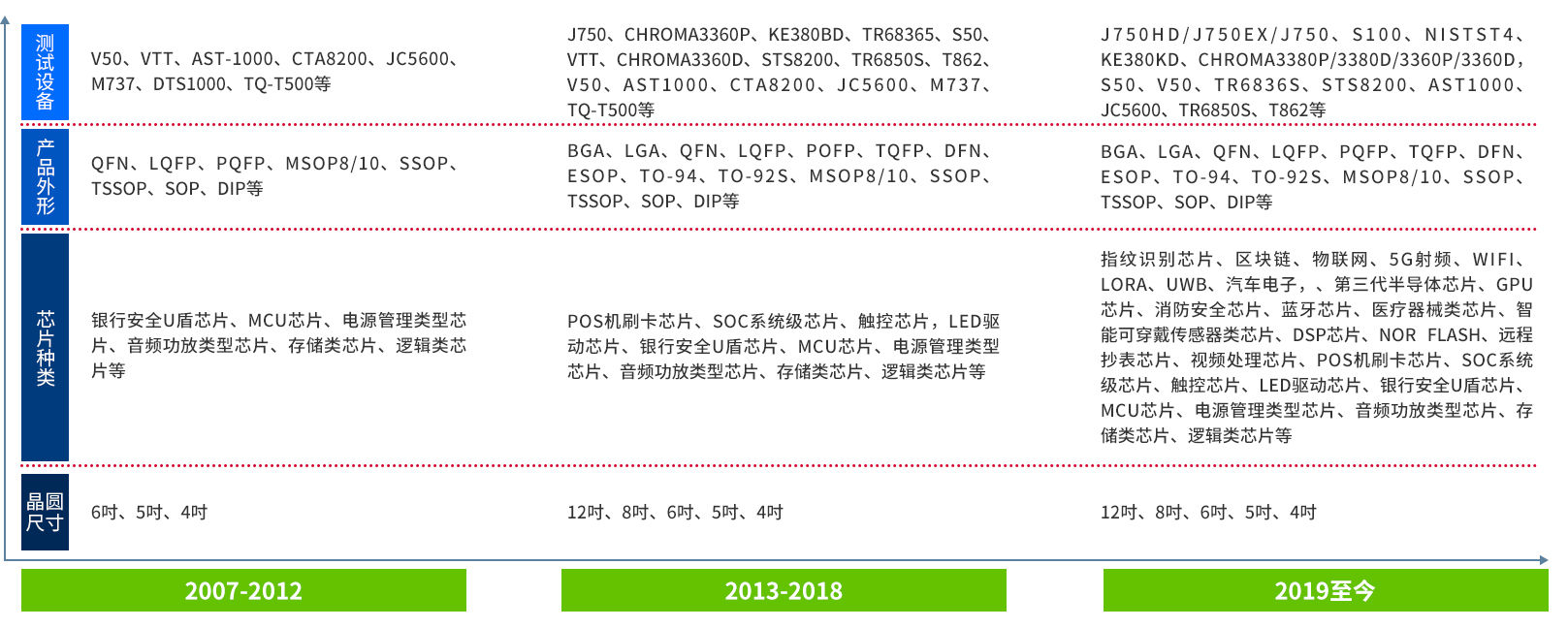

With the continuous rapid development of semiconductor technology and the continuous expansion of semiconductor application fields, the types of semiconductor devices are increasingly rich. Because different application scenarios have different requirements for the function and response speed of semiconductor devices, a large number of devices or chips with various properties and applications coexist, and the technical parameters and manufacturing process level of each device are also different, and the requirements for test systems and test capabilities are becoming higher and higher. With years of rich experience in the testing industry, Huayu team carries out test feasibility assessment and test software and hardware development according to the customer’s chip test scheme, and provides customers with test technology services for the full life cycle of integrated circuit products.

R & D capability

- Evaluate the feasibility of product project development and develop the software and hardware of the test plan according to the chip test plan of the customer

- Develop the programs of various high-end test platforms in the industry (such as j750/v93k/ni), and realize the software and hardware conversion between the programs of each platform.

- It has many mass production test solutions, such as fingerprint identification, touch control, SOC, 32-bit MCU, storage, HD video conversion, RF RF (such as bt/tws/ble/5g/uwb/lna/lora/zigbee/iot/nbiot/filter), industrial control, intelligent wearable, third-generation semiconductor, etc

- For the multi site development of test program, ft 8 site has been mass produced and CP 256 site has been mass produced.

- Design and make load board and test fixture according to product requirements.

- Have the evaluation, design and manufacturing capabilities of prober card.

- Customize special mechanical equipment and related fixtures according to product testing requirements.

Test Roadmap

Test management system

Equipment management

- Probe

- Tester

- Handler

- Tape to tray

- Taping Reel

- Lead Scan

Data analysis

- Test file monitoring and analysis

- Analysis of quality test data

- Product test data analysis

- Automatic yield analysis

- Tester->STDF

- Prober->MAP

Program management

- Test program upload

- Test procedure review

- Test program download

Health monitoring

- Equipment maintenance

- Equipment maintenance

- Daily spot check

- Intelligent early warning

Operation monitoring

- Equipment status

- Yield detection alarm

- OEE

- OUTPUT

- UPH